As a quick disclaimer, this is a post for the menswear nerds. It’s a heavier, more detailed article that breaks into a lot of the technical details about the differences between quality and cheap shoes. If you’re looking for a quick guide on how to find and buy a certain style of shoes or even which styles are appropriate for given scenarios, we suggest trying some of our other articles.

Have you ever wondered what the difference is between a pair of shoes that cost $100 and those that cost $1000. While elements such as quality of leather, name brand, and country of construction are all factors, the largest differentiator is the quality of the construction.

By construction, I mean the method through which the sole is attached to the upper of the shoe. For the sake of reference, here’s a quick breakdown of all the major players in a shoe’s anatomy.

The upper – This is the leather or canvas that is seen above the sole when a shoe is worn. While the upper itself can be broken down into many key points (the vamp, the heel, the eyelets, etc.), as a whole it is everything which actually covers the foot when wearing the shoe.

The insole – This is the material on the inside of the shoe with which the foot is in contact when the shoe is being worn.

The outsole – This is the material on the bottom and exterior of the sole and is what comes in contact with the ground while walking.

The welt– On better-constructed shoes, the welt is a strip of leather which runs along the perimeter of the outsole. Its primary function is for attaching the upper to the outsole.

The last – A three-dimensional model of a foot, the last is what gives a shoe its shape. Lasts are used for both design and construction.

With that basic terminology in mind, we are ready to describe the three basic methods of shoe construction. They are cementing, blake welting, and goodyear welting. All three have their strengths and their weaknesses and no option is objectively superior to any of the others.

Cementing

This is the cheapest, fastest, and most common method of attaching the sole of a shoe. Once the upper is shaped and completed around the last, the sole is attached with an adhesive and no welting is used.

The Pros – It is a cheap, quick way of attaching the sole, making the shoes’ overall price much more aggressive than a pair which is welted. It also is a superior method of attachment for gummy, rubbery soles that are used in casual shoes. Cementing can be a great method for sneakers, bucks, chukkas, and other shoes with a rubber sole.

The Cons – It is a cheap, quick way of attaching the sole, affecting the durability of the connection between the upper and the sole. It is also a method that completely prevents any resoling. Once the upper begins to separate from the sole or the sole itself is damaged, the shoes need to be replaced, rather than repaired.

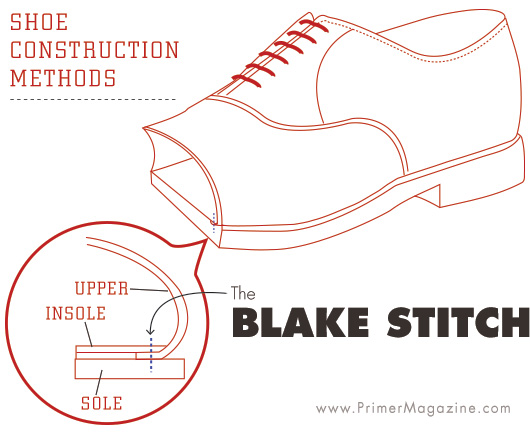

Blake Welting

Of the two primary welting methods, blake is the simplest and most common. It also is a byproduct of the industrial revolution because the stitching is done on the inside of the shoe – making it impossible to do by hand

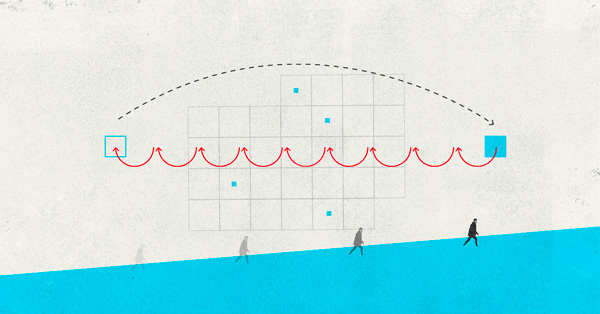

For a blake welt, the upper is wrapped around the insole and attached between it and the outsole. A single stitch attaches everything together.

The Pros – Because it is a simpler construction than a goodyear welt, it is also less expensive. It is a process that allows for resoling once the outsole is worn or damaged. Blake welting is also superior when seeking a close-cut sole. Because there are no exterior stitches, the body of the outsole can be cut extremely close to the upper. Lastly, because it has fewer layers than a goodyear welt, a blake-welted sole is more flexible.

The Cons – While a blake can be resoled, it needs a specific blake machine to do so – making it much more difficult and (sometimes) expensive than resoling with a goodyear welt. While fewer layers make the sole for flexible, they also make it less water resistant. Water can wick up through the sole and begin to pool more quickly and easily. There are also some men who complain about irritation at the bottom of their feet because of the interior stitching.

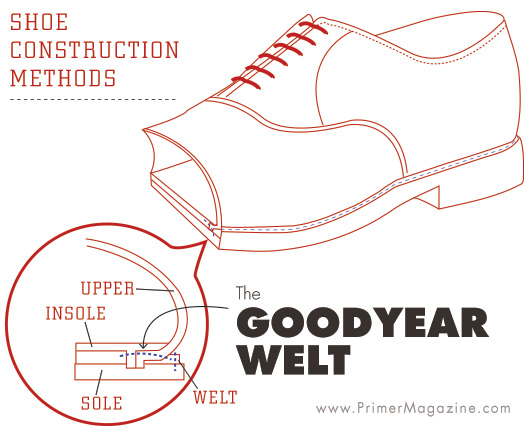

Goodyear Welting

Goodyear welting is the oldest, most labor intensive, and most durable of the three methods of construction. It can be done by machine or by hand and involves multiple steps.

The first part of the process is preparing the insole for stitching. This is done by creating a perpendicular “rib” that runs across the insole. Some shoemakers create the rib by cutting and sculpting the insole, while others will do so by using a supplementary material like linen tape.

The second step is to last the shoe. This is done by stretching the outsole over the last and attaching it, along with the insole, to the last.

Part three is the actual welting. At this point shoe-specific thread is sewn through the welt, the upper, and the insole rib. Through a separate stitch, the welt is attached to the outsole. For both of these stitching points, a lockstitch is used – meaning the chain won’t unravel if it breaks down at any particular point in the shoe.

The Pros – The two-level stitching makes it incredibly easy to resole a goodyear welted shoe. Because the welt acts as a buffer between the insole and the outsole, removing the old sole and attaching a new one can be done by machine or by hand and without a specific machine. The extra layers make the shoe more water resistant and supportive.

The Cons – Because of the additional materials and labor required, a goodyear welted shoe is more expensive. The extra layers that provide more structure come at the cost of flexibility.

No one particular method is objectively superior to any other and they all serve different purposes. Most men are best served by having one or two pairs of classic, timeless dress shoes with a goodyear welt. Along with those two pairs, a man can supplement his wardrobe with a pair or two of a more aggressively styled shoe (double monk, tassle loafer, etc.) in a blake welt if he knows he’s adopting the shoe as a more trendy item. Lastly, he can afford to pick up a few more casual options with a cement sole. The rubbery sole, increased flexibility, and lower price point are great for casual kicks.

While the above list is a recommendation, it is by no means definitive. Each man should take stock of what his needs are and plan accordingly.

![It’s Time to Begin Again: 3 Uncomfortable Frameworks That Will Make Your New Year More Meaningful [Audio Essay + Article]](https://www.primermagazine.com/wp-content/uploads/2025/01/begin_again_feature.jpg)