A Modern Man's Guide to Tools

Strangely enough, this is one of the simplest tools, but it’s also the easiest to screw up, no pun intended. For our purposes, the Screwdriver category consists of a simple metal rod with a shape on its head, designed to fit inside its counterpart, the screw (or bolt). This distinguishes it from the Wrench category, in which the tool fits around its counterpart.

Like all things that screw, the screwdriver shares a “complicated” relationship with its counterpart. To carry the metaphor a little further, if the two parts are not compatible, the one doing the screwing can permanently damage the one getting screwed. Let’s put it in plain terms.

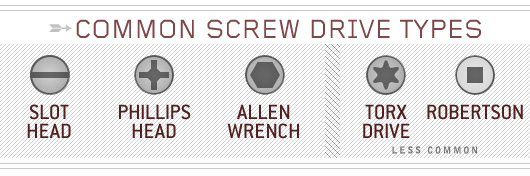

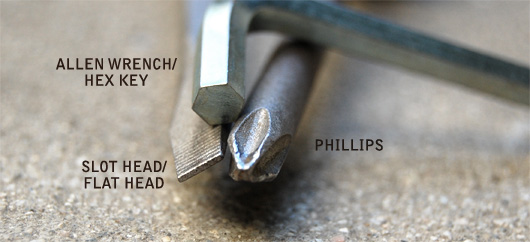

Screws, and screwdrivers, have different types and sizes. The most common types here in the US are Phillips head and slot head. Then there’s the less common Torx or star head, a super cool six-pointed star-shaped head, which is used on things that need to get very tight. Others exist, but let’s not get too complicated.

The Allen wrench is something of a step-child. While a wrench by name, it also falls somewhat into the screwdriver category. It shares the criterion of the tool fitting inside the counterpart, and it shares some of the pitfalls of other screwdrivers. You can even get an Allen-head screwdriver. However, most commonly (and technique-wise), it is more of a wrench. Read on.

→ The Other Kind of Screwdriver

About the drink: According to legend, American petroleum workers in Saudi Arabia (or Siberian, Welsh or Irish coal miners, depending on your ethnic pride) mixed vodka into cans of frozen orange juice, using a screwdriver to stir them together. Whence the name.

You are likely to need a screwdriver for:

- Computers, small electronics

- Wall socket electrical outlets, light switches, and cover plates

- Changing the air filter or hoses in your car

- Furniture fixtures (cabinet & dresser knobs)

Screwdriver Technique

The most important technique is to use the right size screwdriver. While screw size is shrouded in mystery, there are four basic sizes of Phillips screwdriver — from #0 to #4 — #0 being the smallest. The most common sizes are #2 and #1, #2 for standard screw sizes, #1 for “miniature”. Then there are the jeweler-size screws. With slot head screwdrivers it’s even simpler, the blades are measured in fractions of an inch. The point is, before you go all Bruce Willis on a screw, make sure the screwdriver head fits snugly.

The technique of tightening or loosening a screw is pretty simple. Push the screwdriver toward the head of the screw, and then it’s righty-tighty, lefty-loosy. In other words, turn clockwise to tighten (the way a clock’s hands turn), counter-clockwise (or anti-clockwise if you’re speaking the Queen’s English) to loosen.

Screwdriver Pitfalls

The greatest danger of screwdriving (new word, you read it first here) is stripping the screw head. Using the wrong size screw, or trying to over-tighten can damage the screw, making it unusable.

Another danger, as with any pointy object, is cutting yourself, poking your eye out, all those things that Mom warned you about. Be careful. Use the screwdriver for its intended purpose: screwing things. And if you bleed, don’t bleed on this article. We won’t clean it up.

![It’s Time to Begin Again: 3 Uncomfortable Frameworks That Will Make Your New Year More Meaningful [Audio Essay + Article]](https://www.primermagazine.com/wp-content/uploads/2025/01/begin_again_feature.jpg)