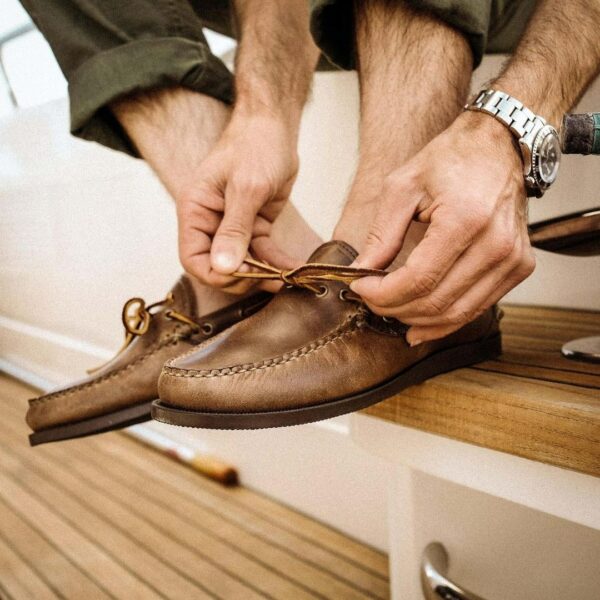

I’ve always chuckled at people who buy the most rugged SUVs with no intention of ever going off-road. So you want the capability, but you don’t want to get the thing dirty…I don’t get it. But if I’m honest, I’ve become that guy when it comes to my footwear; in fact, the first thing I said to my wife when I opened my camp boots from Oak Street Bootmakers was, “Well, I definitely won’t wear these when we go camping. They’re too damned pretty.”

I first stumbled across Oak Street Bookmakers in 2019 when I was putting together a business casual capsule wardrobe for Primer. I’ve always been drawn to American-made footwear, but there was something different about Oak Street: The combination of quality construction, classic style, and a touch of modernity gave Oak Street an aesthetic that was fresh without pretension.

I’ve dropped links to Oak Street’s shoes and boots in a few articles over the years, and this past fall, I finally bought my own pair. The moment I put them on, two thoughts occurred to me: 1. I already want another pair of these. 2. I need to learn more about this company.

I reached out to Oak Street to see if their founder, George, would give me an interview. He was going on leave because his wife was getting ready to give birth, but the company was excited about the idea of an interview. I had the opportunity to video chat with Mike Wilkie, the VP of Marketing. Mike and I spent two hours talking about everything from Oak Street to American history to our favorite film cameras and lenses (he’s a Zeiss guy).

What I learned is that Oak Street is the kind of business that I want to patronize. They value the tradition of American shoemaking. They value their product, and most importantly, they value their customers.

Tell me about how George started the company and brought you in:

I met George in 2009, a year before Oakstreet launched. I was skeptical at first, to me, the biggest indicator of brand quality was longevity. Alden has been making shoes since the late 1800s, so how is this guy going to match that? But George seemed like he was coming from the right place, and I appreciated what he was trying to do. He sent me this pair of shoes, and look at them. I mean, I’ve worn these a few times a week for thirteen years and they look brand new. (At this point, Mike held up a pair of navy suede trail oxfords with a red gum sole. And yes, they still looked brand new)

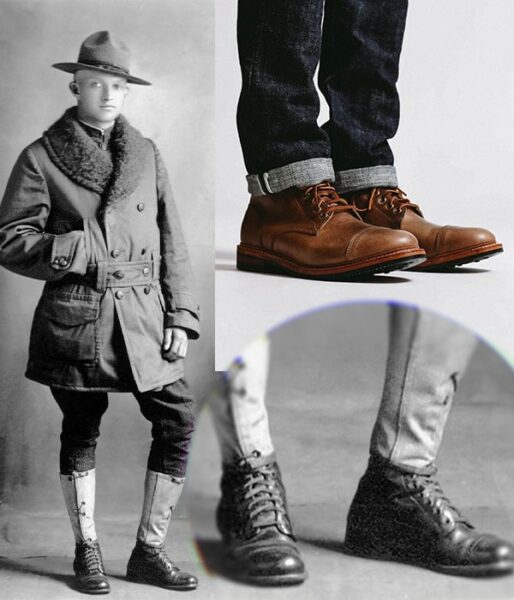

George, who apprenticed in his dad’s cobbler shop, wanted a WWI trench boot, but there wasn’t anything out there that was still made in USA. He tried to find someone who was making this boot, and no one was, so he realized he needed to do it. Since then, we’ve been driven by a simple mission: To preserve the tradition of American shoemaking.

It’s a small company, so we all wear a lot of hats. My background was brand marketing, brand advertising. I saw ecommerce was going to be the future. I started learning Magento when it was in beta, right around that time I met George, who was in the early stages of getting Oak Street off the ground.

George and I are about the same age. We grew up liking that last great era of American menswear when companies like Ralph Lauren and Banana Republic were still making their products in the US. And if they were making it overseas, it was part of the product story; they embraced it.

There are a lot of reasons we want to make things in America, but it’s not about saying America is the only place to make things. It’s fine to make things overseas, but too many companies try to hide it anymore.

How many employees does the company have? How many are factory artisans?

Our numbers change depending on demand. Shoemaking in Maine is a cottage industry, and by that I mean, many of our artisans are literally making these goods in their homes.

The guy who makes our belts makes them at home. We also make some shoes on the West Coast. We are the only company offering a ready-to-wear hand-lasted boot for the average guy.

Part of shoemaking for us is making sure that these are sustainable jobs. We want our shoemakers to be able to make a respectable living from this – we want it to attract young people – it’s not just a fantastic craft – it’s a real part of our history, like blue jeans. American footwear could only have come from here. Moccasins, trench boots, penny loafers, boat shoes – these shoes came about for functional reasons and the styles stuck.

Is there a void in the current boot and shoe market that OSBM fulfills?

Absolutely. We don’t view our competitors as direct competitors. We have a lot of respect for other American brands; however they all do something different from us, which is that they specialize. Nicks does the logger boots, Redwing focuses on trades. Rancourt focuses on handsewns.

What we offer is a collection that includes the full scope from service boots, to outdoor, to mocs, loafers. The reason: we see ourselves less like Nicks and Rancourt, and more like what Allen Edmonds used to be. We make traditional, classic, timeless styles.

We are filling the void for the customer who’s no longer happy with the price-to-quality ratio. We get calls nearly everyday from guys who want to place an order over the phone. These are the guys who have been buying loafers from the same company since 1988, but the quality just isn’t there anymore. Some of those guys are our best customers. Some of these guys send us checks by mail. We love those guys.

The other thing that we do is we introduce these classic, timeless styles to the younger generation. There’s no one brand that makes a respectable rendition of a WWI trench boot AND a loafer and a moccasin. We show younger guys how these styles are still relevant.

But that’s not so much about filling a void. It’s about our mission: carrying on the tradition of American shoemaking. Keeping all of the supply lines alive: laces, heel pads, machine servicers, even the local cobbler.

If a quality issue pops up, we look at it like this: If we can repair it better than your average cobbler can, then we’ll pay to ship it back to us. If a local cobbler can fix it, then we want you to take it there, and we’ll send you a check for reimbursement. Cobblers are an important part of the industry and we want to support them too. The guarantee is simple: If there is something compromising the footwear as a result of the factory, we make it right one way or another.

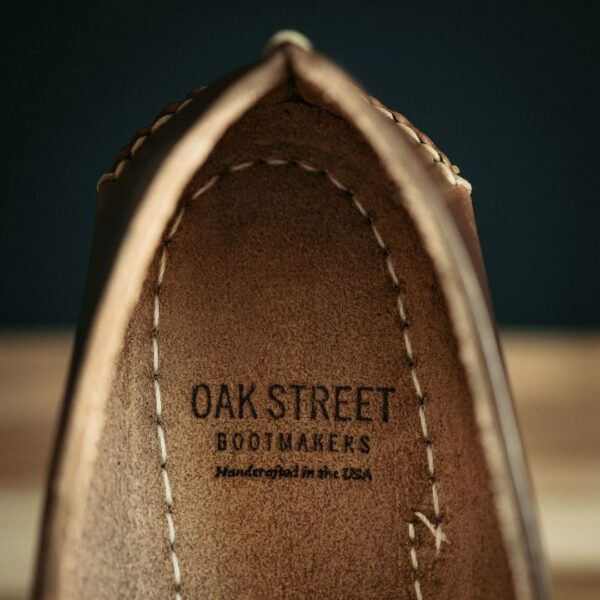

To what degree are your products made in America?

Top to bottom – 100%

We’re very transparent about our suppliers. We list our leathers, the tanneries. We say who made our soles. We’re as transparent as we can be. We even disclose things that could put us at a competitive disadvantage, but it’s important.

It would be easy to move things to the DR. But if we did that, it would be a major blow – not to just the people who work for us directly, but also from all of the suppliers. And that comes back to our mission.

Our mission is the message, it is the glue. It’s the one thing that appeals to everybody. Everybody can respect the desire to preserve American tradition and craftsmanship, and to keep providing sustainable economic opportunities for those in a lot of small towns that have been otherwise forgotten and neglected.

Why are some of the boots unlined? Is there an advantage to this kind of construction?

The first reason is that the outdoor mocs (including the camp boot) are meant for four-season wear. You want to be able to wear these in the summer with light socks or in the winter with thick socks. Chromexcel is already water resistant, so if you line these boots, they won’t breathe well. The other reason is the tradition of the construction. We also want to make sure the products are affordable to as many people as possible.

What’s the design philosophy behind OSBM?

American heritage. But there’s more nuance to it than that. What we’re NOT doing is making reproductions. A great example is our trench boot and our field boot. When you look at the specification commissioned by the armed forces – our objective isn’t always to meet the spec (and we usually exceed the spec): our objective is to maintain the spirit of those pieces.

We’re inspired by men like General Pershing from WWI. This guy was General of the Armies of the United States. First person to ever receive this rank. He was asked by congress to get a million plus troops ready for war within a year. The first thing that he did was work up the specs for the trench boot, the M1918 boot. He knew if we were going to fight trench warfare, field shoes were not going to cut it. When people were training in the field, he would go around and inspect their boots, inspect their hobnails, make sure they were polishing appropriately with wax. This guy oversaw development of 9 different iterations of this trench boot, personally, in just a few years.

So when we look at our trench boot, what we want to preserve is the spirit of General Pershing – we’re forever trying to push the limits of the specification to make the highest quality boot that we can while keeping the budget of our customer in mind.

Your website says all of your footwear is recraftable. What’s that process look like and how much does it cost?

The recrafting is part of the reason for buying the product. It’s about being able to get that factory finish. It’s not really profitable for us, but it’s important to us that people can renew their footwear. $120 includes our in-house rubber and leather soles. And then we have a higher tier for specialty soles: $150. Prices may have to change soon because we’re seeing a lot of the inflationary pressures come to our suppliers, and now they’re coming to us.

Is the long term goal to sell through large retailers, or do you want to keep the operation small and private? Basically, where do you want to see the company in five years?

We want to do as much of what we’re doing as we possibly can. We want to make more styles, more limited editions, and reach more customers. If there’s a retailer who can help us reach that goal, then we’re happy to work with them. We want as many people to have access to our products as possible.

We don’t discriminate: We’re ready to work with whoever wants to work with us.

For people who want something rare, we have limited editions. We go all out with our limited editions; each detail is done by hand – and we don’t worry about making those as budget-friendly. We also don’t ever artificially limit our limited editions. We make as many as we can afford, and when they’re gone, they’re gone.

Is there anything else you want our readers to know?

I can’t overstate how small we are. People don’t see that. We’ll post a picture to our Instagram, and people will ask things like “What pants is your model wearing?” And I’m like, model? No…it’s me. I took this picture in my home office. I’m doing the editing, the copywriting. Yesterday I edited some photos. I fixed a bug on our website. I had to rerun our product database with all of our most updated costs because of the supply squeeze.

Countless times it’s been George and me transporting inventory with a Uhaul. George brings his vacuum from home to clean our headquarters. And Hayley, our incredible Operations Manager, still personally responds to nearly every email and phone call. Seriously, we’re a small operation.

→ Check out Oak Street Bootmaker's website

![It’s Time to Begin Again: 3 Uncomfortable Frameworks That Will Make Your New Year More Meaningful [Audio Essay + Article]](https://www.primermagazine.com/wp-content/uploads/2025/01/begin_again_feature.jpg)